Introduction

For decades, custom t-shirt printing in the UK involved trade-offs: high minimum orders, long lead times, and limited design capabilities. Traditional methods like screen printing and vinyl often restricted creativity and required costly setups, making it difficult for small businesses, creatives, or individuals to achieve professional results.

Direct-to-Film (DTF) printing has changed the game. It combines vibrant colour reproduction, unmatched durability, and fabric versatility with the ability to print single pieces or bulk orders efficiently. At Sunygraphics, we’ve perfected the DTF workflow, delivering premium, ready-to-wear custom apparel to clients across the UK with ease.

This guide walks through our process from concept to delivery and explains why DTF printing makes custom t-shirt production truly effortless.

Step 1: Upload or Create Your Design

Every great t-shirt starts with a well-prepared design. Sunygraphics works with both:

-

Client-supplied artwork: Logos, illustrations, photographs

-

Custom designs created with our team: For clients without ready-to-print files

Key design considerations:

-

Resolution: Minimum 300 dpi for crisp prints

-

Colour Accuracy: Using RGB or CMYK depending on the print workflow

-

Transparency and Layer Management: Essential for complex graphics

We provide guidance to ensure your design translates perfectly from screen to fabric, maintaining clarity, vibrancy, and detail.

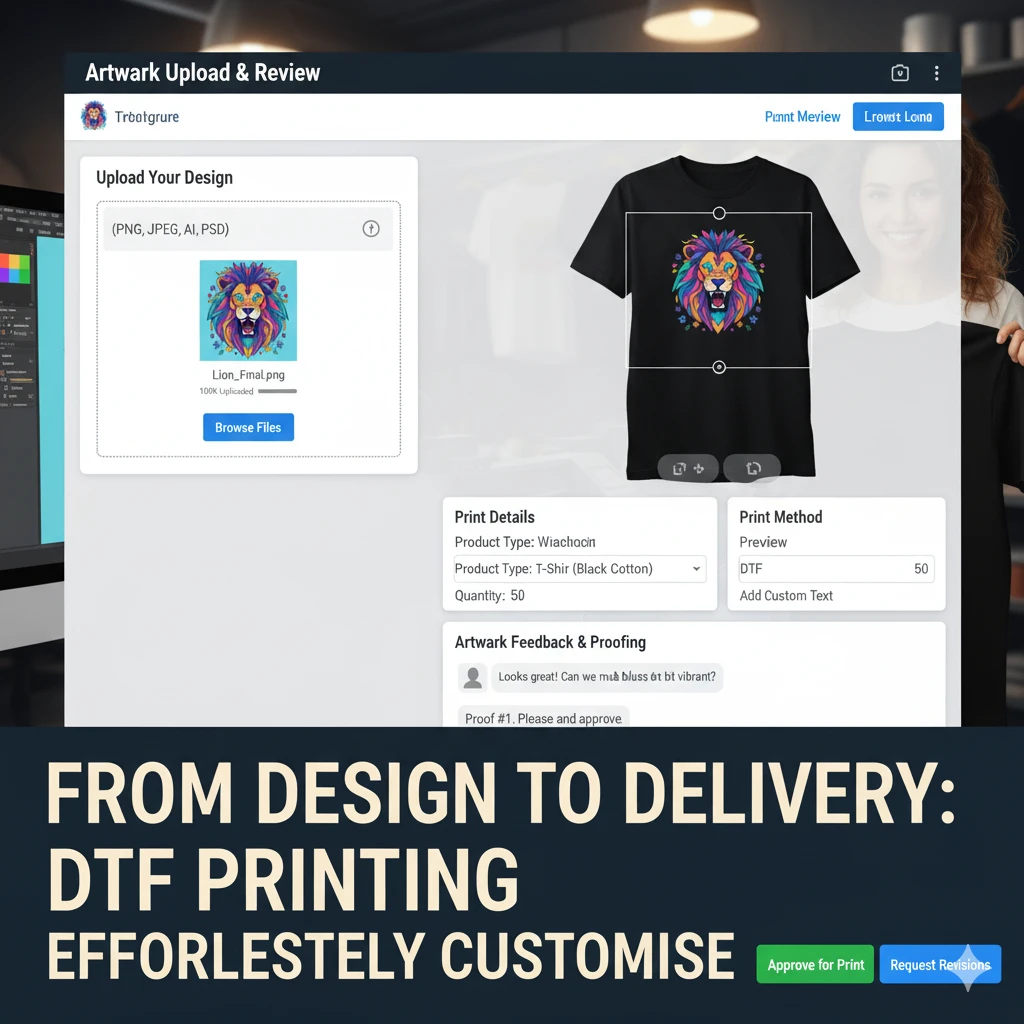

Take control of your custom apparel project with our easy-to-use artwork upload and review system. Get visual proofs, provide feedback, and approve your designs confidently.

Step 2: Select Your Garment

Choosing the right garment is critical to both comfort and aesthetics. Sunygraphics offers a wide variety:

-

T-Shirts: Classic cotton, premium fits, blended fabrics

-

Hoodies & Sweatshirts: Ideal for merchandise or cold-weather events

-

Polos & Workwear: Professional branded apparel

-

Accessories: Tote bags, aprons, and other promotional items

We guide clients in selecting the perfect fabric, cut, and colour combination to complement their design, ensuring every shirt feels as good as it looks.

Ready for anything! Our DTF technology is designed for versatility, transforming a wide range of apparel types into custom masterpieces with your unique designs.

Step 3: DTF Printing Explained

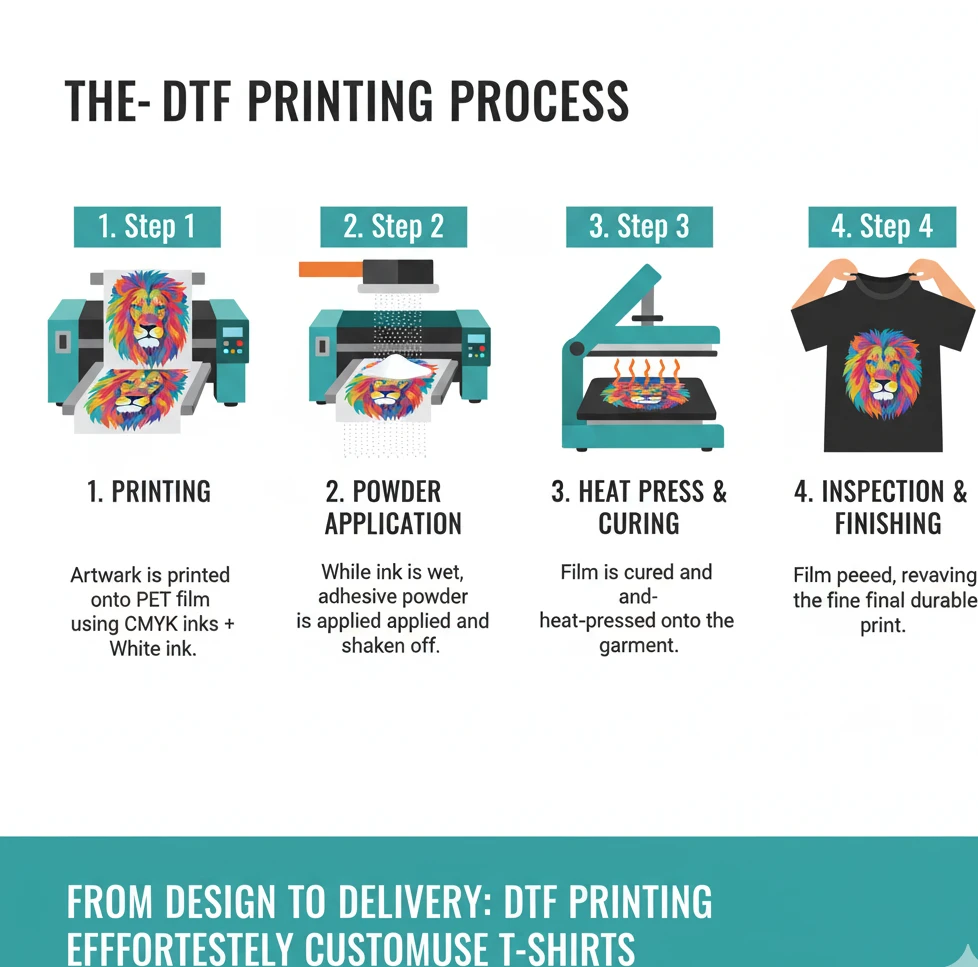

Direct-to-Film printing is a multi-step process that guarantees vibrant, durable results:

-

Printing the Film: The design is printed onto a special DTF film with high-resolution inks.

-

Powder Adhesive Application: A powder adhesive is applied to the printed film for durability.

-

Curing and Heat Transfer: The design is heat-pressed onto the garment, fusing the ink and adhesive to the fabric.

-

Finishing and Quality Checks: Every garment is inspected for colour fidelity, alignment, and print integrity.

The result is a flexible, long-lasting print that works on cotton, polyester, blends, and even dark fabrics — all without pre-treatment.

Step 4: Quality Assurance and Attention to Detail

Every order undergoes meticulous quality control, including:

-

Checking print alignment and sizing

-

Verifying colour accuracy against original artwork

-

Ensuring adhesion and wash resistance

-

Inspecting garment integrity and finishing

This guarantees that every t-shirt leaving our studio meets premium standards, whether it’s a single order or a bulk batch.

Our commitment to excellence means every printed garment is thoroughly inspected. Here, we’re making sure your vibrant designs stand out perfectly, down to the last detail.

Step 5: Fast, Reliable Delivery Across the UK

Sunygraphics understands the importance of timely delivery:

-

Single orders: Typically 2–3 working days

-

Bulk orders: 7–10 working days depending on volume

All orders are carefully packaged to prevent damage during transit. Local UK production ensures faster shipping, minimal delays, and responsive support for clients.

From design concept to doorstep delivery—we ensure your high-quality, custom t-shirts arrive safely and looking perfect, completing the DTF workflow.

Step 6: Post-Order Support and Reordering

DTF printing isn’t just about delivery; it’s about building a seamless client experience:

-

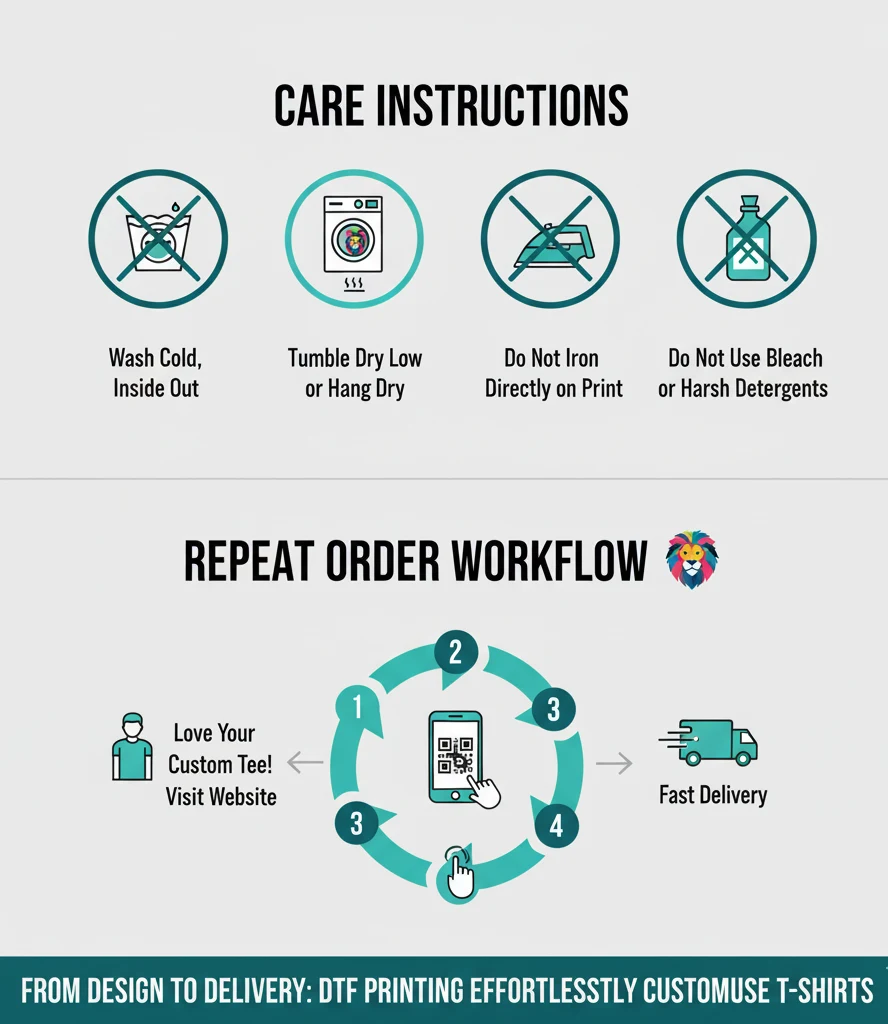

Care Guidance: Wash inside out, cold water, and air dry to extend print life

-

Feedback & Adjustments: Clients can request minor tweaks for future orders

-

Easy Reordering: Past orders can be quickly replicated for consistency in campaigns or events

This ensures clients get consistent, reliable results every time.

Maximize the life of your custom t-shirts and enjoy effortless reorders. This graphic outlines how to care for your DTF apparel and get your favorite designs delivered again quickly.

Step 7: Case Studies – Making Customisation Effortless

Corporate Branding

A London-based fintech startup needed 300 branded shirts for a company conference. Sunygraphics:

-

Reviewed their logo for optimal print clarity

-

Selected soft cotton shirts with high-contrast logos

-

Delivered all shirts within 7 working days, fully inspected

Outcome: Professional-looking shirts impressed clients and employees, reinforcing the brand’s identity.

Event Merchandise

A festival in Manchester required 500 t-shirts with photographic-quality graphics. DTF enabled:

-

Full-colour, high-resolution prints

-

Durable shirts that attendees wore long after the event

-

A quick turnaround that matched the festival timeline

Outcome: Organisers received positive feedback, and the t-shirts doubled as memorable keepsakes, extending their marketing reach.

Personalised Gifts

A client wanted 10 family reunion t-shirts with each member’s portrait. DTF allowed photo-realistic prints on soft cotton, producing gifts that became cherished mementos.

Step 8: Why DTF Printing is the Effortless Choice

-

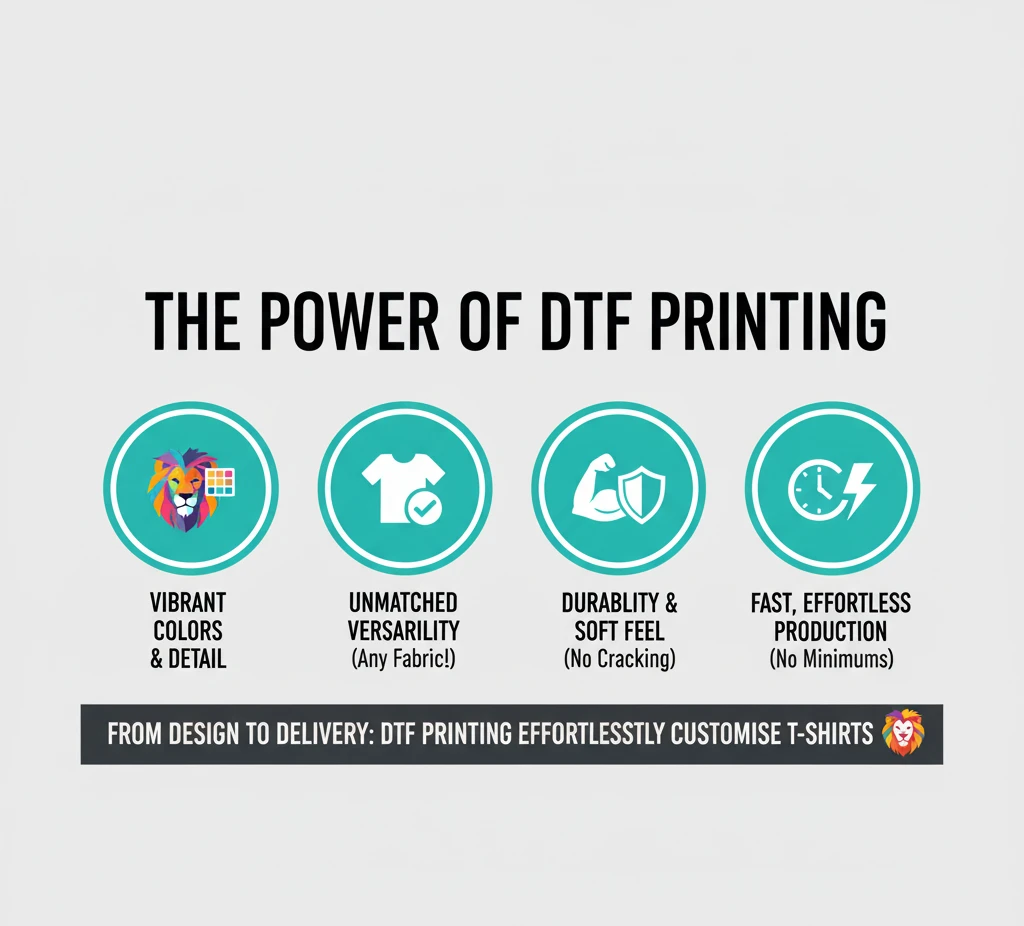

Flexible Quantities: Print 1 or 1,000 shirts without issue

-

Design Freedom: Full-colour, gradients, photographic prints

-

Fabric Compatibility: Works on cotton, blends, polyester, dark fabrics

-

Durability: Wash-resistant prints that don’t fade or crack

-

Speed: Faster production and turnaround than screen printing

Sunygraphics combines DTF technology, professional design support, and rigorous quality control to make custom t-shirt production smooth, fast, and stress-free for every client.

Discover the game-changing advantages of Direct-to-Film printing! From incredible color depth and detail to printing on virtually any fabric with a soft, long-lasting finish, DTF offers unparalleled benefits for all your custom needs.

Conclusion

Custom t-shirt printing has evolved from a complex, costly process into an effortless, accessible, and professional experience thanks to DTF technology. At Sunygraphics, we’ve fine-tuned the workflow so that clients in the UK can go from design to delivery seamlessly, with vibrant, durable, and high-quality results every time.

Whether you’re creating corporate branding, event merchandise, retail apparel, or personalised gifts, Sunygraphics makes customisation simple, efficient, and reliable.

Call to Action: Transform your t-shirt ideas into reality today. Start your order with sunygraphics and experience the effortless power of professional DTF printing.